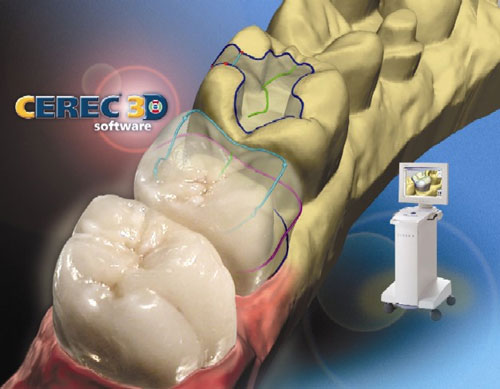

What is cerec?

CEREC (Chairside Economical Restoration of Esthetic Ceramics, or CEramic REConstruction) is a CAD and CAM method developed by W. Mormann and M. Brandestini at the University of Zurich in 1980 for reconstructing tooth restorations. This time-saving, computer-aided process allows dentists themselves to efficiently construct, produce, and insert individual ceramic restorations directly at the point of treatment (chairside) in a single appointment. The first applications were successfully carried out on patients in 1985.

General

In dentistry, the term CAD/CAM refers to the digital workflow of a tooth restoration treatment. This process entails making a digital impression, constructing the restoration on the computer (computer-aided design), and manufacturing the restoration (computer-aided manufacturing). In order to carry all of these steps out in the dentist s office chairside the dentist requires an imaging unit with an intraoral camera, the corresponding construction software, and a milling machine. If the dentist is not looking to carrying out the entire treatment process at the office, they do not need a milling unit, but can instead send the CAD/CAM data to the dental laboratory via an online portal. The lab takes over the next few steps and then sends the finished restoration back to the dentist s office. Around 38,000 dentists worldwide use the CEREC method and thus produce some 6.9 million restorations each year (as of October 2013).

Model History

The CEREC method was developed by Prof. Werner H. Mormann and Dr. Marco Brandestini at the University of Zurich in 1980. The first patient was treated with CEREC using VITABLOCS Mark I ceramic blocks in 1985. Siemens obtained the license to market and further develop the CEREC method in 1986 and launched the world s first CAD/CAM system in dentistry in the form of CEREC 1 in 1987. The areas of indication of the CEREC 2 system introduced in 1994 comprised inlays, onlays, crowns, and veneers. In 1997, the sale of Siemens AG s dental division resulted in the company Sirona. The Windows-based CEREC 3 system was introduced in 2000. While these first three models were based on 2D technology, 3D software introduced in 2003 allowed dentists to construct restorations based on virtual three-dimensional models using the computer. While for some time it was only possible to attach all-ceramic crowns adhesively, the increased precision of the new generation of milling machine, MC XL, which was launched in 2007, made it possible to attach crowns using dental cement. In 2009, Sirona switched to a new imaging technology, the CEREC Bluecam, which is based on short-wave blue light, thus significantly increasing the level of precision in comparison to the previous 3D camera. Since 2010, the use of Biogeneric has made it possible to individually reconstruct the occlusal surfaces of damaged or missing teeth, while achieving a natural look. An interdisciplinary research group headed by Prof. Dr. Albert Mehl of the University of Zurich and Prof. Dr. Volker Blanz of the University of Siegen discovered that all of a patient s teeth have individual characteristics that can be applied from one tooth to another. Launched in 2011, the 4.0 version of the software simplified the user interface with intuitive menu navigation. Since then, it has also been possible to work on several restorations within a single process (multiple restorations). The latest development is the CEREC Omnicam intraoral camera, which was launched on the market in 2012 and facilitates powder-free digital impressions in natural colors.

Technology

During a chairside treatment, the dentist carries out all the steps, from digital impressions and computer-based construction of the restoration to the milling process, inside their office. The dentist uses an intraoral camera to take a photo of the preparation, the antagonist teeth, and the bite situation. Based on the images, the CEREC software creates a virtual model of the patient s tooth situation. The dentist uses this model to construct the tooth restoration on the screen and then passes on the finished construction within the office s network or sends it wirelessly to a milling machine. Depending on the type of restoration, it is then milled out of a color-matched ceramic block in just 6 to 15 minutes using diamond-coated milling units. The dentist can then add the finishing touches to the restoration by painting, polishing, and glazing it, before cementing it (the more traditional option) or adhesively integrating it, depending on the type of ceramic used.

Indications and materials

Silicate ceramics (feldspar and glass ceramics) in particular are ideal for single tooth restorations (inlays, onlays, crowns, and veneers) in the front and on the sides of the mouth. The comparably low flexural strength of 100 to 450 megapascals makes adhesive attachment necessary. Lithium disilicate is a glass ceramic, yet exhibits the material characteristics of oxide ceramics. It is exceptionally strong and translucent. Oxide ceramics in particular are ideal for manufacturing high-strength bridge frameworks and crown copings in the front and on the sides of the mouth. Flexural strength of 300 to 600 megapascals (infiltration ceramics) or 600 to 1,300 megapascals (polycrystalline oxide ceramics) ensures a high level of long-lasting durability and breaking strength.

Benefits

CEREC technology makes it possible to produce and integrate ceramic restorations in a single appointment. Unlike other materials such as amalgam or gold, ceramic is more biocompatible and boasts tooth-like physical and aesthetic qualities. In addition, digital impressions are more comfortable for patients than traditional impressions.

By further developing the process, it was possible to reduce the amount of follow-up work and time-intensive occlusion adjustment that was often necessary in the past. According to studies, the ten-year lifespan of CEREC inlays polished and milled with the aid of a computer is not only significantly longer than that of gold inlays, but also exceeds that of individually laboratory-manufactured ceramic inlays. Further clinical studies reveal that the success rate of CEREC restorations is 95.5 percent following a period of nine years and 84 percent after 18 years.

Other potential applications

Combined with three-dimensional X-ray technology, it has also been possible to use CEREC for implants since 2009. The dentist can combine the CAD/CAM planning based on CEREC with 3D X-ray data in order to coordinate the prosthetic and surgical implant planning and achieve the intended treatment results. Based on this so called integrated implantology, the dentist is able to order the drilling templates from the drilling template manufacturer SiCat or if they have their own milling machine produce them on their own at the office using CEREC Guide.